The Critical Truth About Insulation and Fire Safety

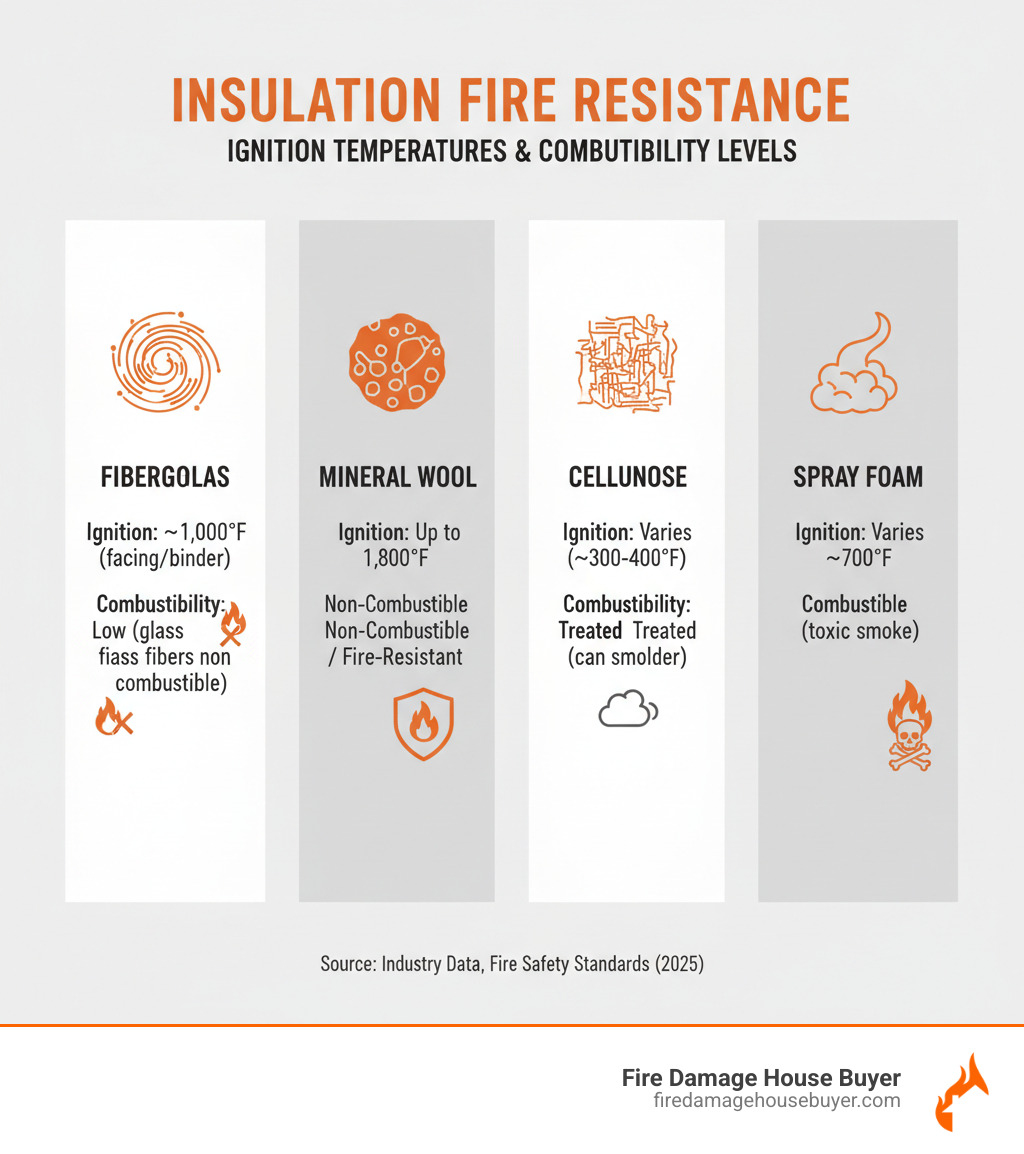

Does house insulation burn? Yes, some types of house insulation can burn. While others are non-combustible, they often have flammable components. Here’s a quick overview:

- Fiberglass insulation – The glass fibers won’t burn, but paper or foil facings can ignite at temperatures above 1,000°F.

- Mineral wool (rockwool) – Non-combustible and fire-resistant up to 1,800°F, making it the safest option.

- Cellulose insulation – Made from paper treated with fire retardants; it can still smolder or burn if untreated or degraded.

- Spray foam insulation – Ignites around 700°F and produces thick, toxic smoke when burning.

The flammability of your home’s insulation isn’t a simple yes-or-no question. Materials like mineral wool are nearly fireproof, but others pose serious risks, especially if installed improperly near heat sources. Fires involving insulation contribute to over 51,000 home fires annually, causing nearly 500 deaths and $1.3 billion in property damage.

For homeowners recovering from a fire, insulation damage is more than meets the eye. It releases toxic fumes, gets contaminated with soot, and can hide structural damage. Restoration is complex and expensive, often costing tens of thousands for insulation replacement and related repairs alone.

I’m Daniel Cabrera, and over my 15 years buying fire-damaged properties, I’ve seen how insulation plays a critical role in both fire spread and recovery costs. Understanding does house insulation burn helps homeowners like you make informed decisions about restoration—or whether selling as-is might be the smarter path forward.

Understanding Insulation Flammability: What Makes Insulation Burn?

The question does house insulation burn is complex because a material’s fire risk depends on several factors. The first is the difference between combustible materials, which burn, and non-combustible ones, which don’t. The catch is that even non-combustible insulation often has flammable components like paper facings, foil backings, and binding agents that can ignite.

Manufacturers often add fire retardant chemicals that create a protective char layer or interrupt combustion, slowing a fire’s spread. You can learn more on how flame retardants function. However, these treatments can degrade over time, especially with moisture exposure. Other key factors include a material’s ignition temperature (the point of spontaneous combustion) and the flammability of its binding agents and facings. These components can catch fire at much lower temperatures than the insulation core, creating a hidden hazard in your walls. This complexity is why assessing fire damage is so difficult and why a professional House Fire Damage Restoration Guide is necessary to understand the full scope of repairs.

How Fiberglass Insulation Reacts to Fire

Fiberglass is classified as non-combustible by U.S. building codes, but that’s not the full story. The glass fibers themselves have a melting point above 1,000°F and won’t burn. However, the binding agents holding the fibers together can ignite at these high temperatures, releasing smoke. The biggest risk comes from the combustible paper or foil facings on many fiberglass batts, which can catch fire at much lower temperatures. If these facings are exposed or improperly installed, they pose a significant fire hazard.

How Mineral Wool Insulation Reacts to Fire

If you’re looking for the gold standard in fire-resistant insulation, mineral wool is it. Also known as rockwool or slag wool, this material is inherently non-combustible. Its melting point exceeds 1,800°F, which is hotter than most house fires. When exposed to flames, mineral wool doesn’t ignite, melt easily, or contribute to fire spread. It’s often used as a fire block in fire-rated walls and produces minimal smoke, making it the top choice for fire safety.

How Cellulose Insulation Reacts to Fire

Cellulose insulation is made from recycled paper products, which are naturally flammable. To counteract this, it’s heavily treated with borate fire retardants, earning it a Class 1 Fire Rating. When exposed to flames, treated cellulose chars instead of burning, creating a protective barrier that slows fire progression. However, untreated or improperly treated cellulose is a danger, and even treated material carries a smoldering risk near heat sources. The fire retardants can also lose effectiveness over time, especially if exposed to moisture.

How Foam Insulation Reacts to Fire

Foam insulation, including spray foam and rigid foam boards, is combustible despite being treated with fire retardants. Spray foam ignites at approximately 700°F and can sustain rapid combustion. The greatest danger is the thick, toxic smoke it releases when burning, which poses extreme health risks. For this reason, building codes mandate that foam insulation in interior applications must be covered by a thermal barrier, like 1/2-inch drywall, to prevent it from igniting and accelerating fire spread.

Does House Insulation Burn? A Comparison of Common Types

When homeowners ask does house insulation burn, the answer depends on the type. Each material has a different fire performance, which impacts your home’s safety and post-fire restoration options. Mineral wool is the most fire-resistant, while spray foam is the most combustible and produces toxic smoke. Fiberglass fibers are non-combustible, but their paper facings can burn. Cellulose is treated with fire retardants to make it char instead of burn, but this protection can degrade. The table below compares these common types.

Understanding these differences is crucial after a fire, as it helps determine whether to restore or consider other options, like Cleaning Up After a House Fire. The material also impacts restoration costs. Replacing insulation can cost $2,000 to $8,000, but that’s just the start. Factoring in debris removal, structural repairs, and code upgrades, the total investment becomes overwhelming for many homeowners.

| Insulation Type | Combustibility | Ignition Temperature | Smoke Production | Required Fire Barriers |

|---|---|---|---|---|

| Fiberglass | Non-combustible fibers, combustible facings/binders | >1,000°F (fibers), lower for facings | Low (fibers), higher for facings | Yes, for exposed facings |

| Mineral Wool | Non-combustible | >1,800°F | Minimal | No |

| Cellulose | Combustible (treated to resist fire) | ~400°F (treated) | Moderate (charring) | Yes, treated with fire retardants |

| Spray Foam | Combustible | ~700°F | High, toxic | Yes, thermal barrier (e.g., drywall) |

Fire Safety Regulations, Health Risks, and Prevention

Fire safety regulations for insulation are designed to save lives. The key standard is ASTM E84, which measures the Flame Spread Index (FSI) and Smoke Developed Index (SDI). Lower numbers mean better fire performance. Building codes use these ratings from organizations like the American Society for Testing Materials to dictate how insulation must be installed. For homeowners facing fire damage, bringing a property up to current code during restoration can be a surprising and significant expense, adding to the Legal Financial Considerations After Fire.

Can Insulation Cause a Fire?

While insulation rarely starts a fire on its own, improper installation can create the conditions for one. The most common issues include:

- Electrical Wiring: Packing insulation too tightly around non-rated wiring can cause it to overheat and ignite nearby combustible materials, like paper facings.

- Recessed Lighting: Non-IC-rated (Insulation Contact) light fixtures require clearance from insulation. Covering them can trap heat and lead to a fire.

- Heat Sources: Chimneys, furnace flues, and hot water pipes must have proper clearance from all insulation types to prevent heat transfer and ignition.

- Arcing Fires: Damaged or faulty wiring can create sparks hot enough to ignite insulation, especially foam or paper-faced products. The Electrical safety information from the CPSC offers guidance on preventing these hazards.

What are the health impacts of insulation exposed to fire?

Burning insulation releases a dangerous mix of toxic fumes and particles. The most immediate danger is smoke inhalation and respiratory damage. Other serious health risks include:

- Carbon Monoxide: This odorless, colorless gas is produced in all fires and can be lethal.

- Toxic Chemicals: Burning foam insulation releases styrene, which can cause Central nervous system (CNS) depression, while some binders release formaldehyde, a known irritant and suspected carcinogen.

- Hazardous Debris: Handling burnt insulation without protection can cause skin and eye irritation and release harmful particles into the air. In older homes, this debris may contain asbestos, which can cause severe lung diseases.

How can you improve insulation fire safety?

Taking proactive steps can significantly reduce your home’s fire risk. Here are the most effective measures:

- Ensure Professional Installation: A qualified installer will follow all building codes and clearance requirements for heat sources and electrical fixtures.

- Choose Non-Combustible Materials: Using mineral wool provides the highest level of fire protection.

- Install Thermal Barriers: Combustible materials like spray foam must be covered by a thermal barrier, such as drywall, as required by code.

- Conduct Regular Inspections: Annually check your attic for damaged wiring, scorch marks, or displaced insulation.

- Maintain Proper Ventilation: Good airflow in attics and crawl spaces helps prevent dangerous heat buildup.

- Install and Test Smoke Detectors: Place detectors on every level of your home, test them monthly, and replace batteries annually.

The Aftermath: The Challenge of Burnt Insulation

After a fire, burnt insulation presents challenges that often make homeowners reconsider restoration. The problem is far more complex than what you see on the surface.

First, there’s hidden damage. Fire can smolder inside walls and attics, quietly compromising wooden framing and electrical systems. Without thermal imaging, you can’t know the full extent of the damage. Next, soot and smoke contamination is a major issue. Microscopic smoke particles saturate any remaining insulation, rendering it unsafe and ineffective, posing ongoing health risks. Compounding this is water damage from firefighting. Insulation, especially cellulose, soaks up water, leading to mold, added weight on ceiling joists, and further structural concerns.

A structural integrity assessment by an engineer is essential but adds time and expense. The high cost of restoration is often the biggest shock. Replacing attic insulation might cost $5,000 to $15,000, but that’s just one piece. Smoke remediation, water mitigation, mold treatment, and structural repairs can easily push the total to $50,000-$150,000 or more. The health hazards of cleanup are also severe, as burnt insulation debris contains toxic residues that require professional handling.

This is the point where the reality of a long, expensive, and stressful Fire Damage Restoration Repair process sets in. Many homeowners realize the question isn’t can they restore, but should they. It’s why so many explore whether to Rebuild or Sell After House Fire. Selling as-is offers a simpler path forward, avoiding months of disruption and financial uncertainty.

Frequently Asked Questions about Insulation and Fire

Over my years working with fire-damaged homes, I’ve heard the same worried questions from countless homeowners. Here are straight answers to the most common ones.

Can attic insulation catch fire?

Yes, attic insulation can catch fire. While some insulation materials are non-combustible, fires often start from external sources. The most common culprits are electrical malfunctions (faulty wiring, arcing), overheating light fixtures (especially non-IC-rated recessed lights buried in insulation), and proximity to other heat sources like chimneys. The flammable paper or foil facings on some insulation types can ignite easily, allowing fire to spread quickly and undetected within attics and walls.

Which type of insulation is the most fire-resistant?

Mineral wool is the most fire-resistant common insulation material. It is inherently non-combustible and can withstand temperatures above 1,800°F. Unlike other types that may have flammable components or rely on chemical treatments, mineral wool acts as a natural fire barrier, helping to slow the spread of flames.

What should I do with insulation after a house fire?

Burnt insulation is hazardous material and should only be handled by professionals. It contains toxic residues and can hide severe structural damage. Any insulation exposed to smoke or water is ruined, having lost its effectiveness and posing health and mold risks.

The reality is that replacing insulation is part of a massive, complex restoration project. This includes professional smoke and soot remediation, water damage repair, mold removal, and structural assessments, with costs easily reaching $20,000 to $50,000 or more. The process can take months, filled with stress and uncertainty. This is why a House Fire Damage Restoration Guide is essential, but it also highlights why many homeowners decide restoration isn’t worth the financial and emotional toll. Selling your home as-is provides a way to move forward quickly without dealing with the chaos of repairs.

Conclusion

So, does house insulation burn? As we’ve seen, the answer is nuanced. Mineral wool is highly fire-resistant, while spray foam is combustible and produces toxic smoke. Fiberglass has flammable facings, and cellulose relies on chemical retardants that can degrade. The key takeaway is that while the material matters, proper installation is even more critical to prevent fires from starting near wiring, lighting, and other heat sources.

When insulation does burn, the damage is never isolated. It signals deeper problems like hidden structural damage, widespread soot contamination, and water damage from firefighting. The restoration process is complex, expensive—often costing tens of thousands of dollars—and takes months of stressful work.

We’ve seen countless homeowners face this overwhelming reality and decide they just want it to be over. That’s why Fire Damage House Buyer exists. We offer a simple alternative: we buy fire-damaged houses as-is for cash. No repairs, no cleaning, no commissions. You can avoid the headaches of restoration and get a fair cash offer quickly. This allows you to move forward with your life instead of being stuck in a costly and emotionally draining repair project.

If you’re feeling overwhelmed, you have options. Learn how you can Sell Fire Damaged House and start your next chapter. Contact us for a no-obligation cash offer today and get a clear path forward in days, not months.